Table of Contents

Ultrasonic

Ultrasonic: The term ‘ultrasonic’ is used in acoustics to denote the frequencies which are beyond the range of human hearing. Thus ultrasonic waves are sound waves of frequencies above about 20 kHz.

Ultrasonic waves are not electromagnetic waves and the study of these waves and their applications do not strictly fall under electronics, but most of the applications in the industry involve considerable electronic circuitry and technique.

In comparison to X-rays, ultrasonics encompasses a region where the frequency is much lower. Ultrasonics can currently be produced for frequencies as high as 1000 MHz. Ultrasound is widely used in industry and as an important tool in the medical field. Ultrasonics can be prepared by the magnetostriction effect or the piezoelectric effect.

Generation of Ultrasonic Waves

There are many ways of producing ultrasonic waves depending upon the intended application and the wavelength. A few of these are:

- Mechanical generators

- Thermal generators

- Magnetostriction generators

- The Piezo-electric generator

The magnetostriction generator and the piezo-electric generator are most popular.

Magnetostriction Generation Effect

When a rod or tube of a ferromagnetic material is brought into a magnetic field parallel to its length, the length gets changed slightly. The change in length is independent of the sign of the field and this change may be either a decrease or increase, depending on the nature of the material, its previous treatment, the degree of earlier magnetization, and the temperature. This phenomenon is called the magnetostriction effect. If the applied magnetic field is alternating in nature then the rod or tube placed in the field will contract and expand alternately with a frequency that is twice the frequency of the applied magnetic field. The longitudinal expansions and contractions produce ultrasonic frequencies. The frequency of vibration is a function of the dimensions of the magnetostrictive material and the mode of vibration.

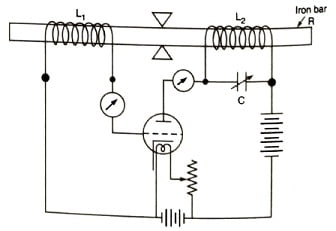

The above figure shows the circuit for producing magnetostriction vibration due to Pierce. The figure shows an iron rod R in clamped in the middle between two knife edges. Coil L2 wound on the right hand portion of the rod, along with capacitor C forms the resonant circuit of the oscillator. Coil L1 wound on the left hand portion of this rod is connected in the grid circuit. By suitable choice of the value of the condenser C, high frequency oscillation currents are set up in the circuit coil L2. The high frequency current flowing in coil L2 results in a periodically varying magnetic field. This produces alternate compression and extension of the bar.

An induced coil is now set up in coil L1 due to the alternate compression and extension of the bar (inverse magnetostrictive effect). The induced emf in coil L1 now amplifies it producing a higher value of current in L2. This in turn produces a higher emf in coil L1 (inverse magnetostrictive effect) thus reinforcing it. In this way, the coil L2 current ultimately rises to a very large amplitude with a frequency limited by the longitudinal frequency of the rad. If the frequency of the circuit equals the frequency of vibration of the rod, then resonance takes place and sound waves of maximum amplitude are produced. By varying the length of the rod and the capacitance, the frequency can be varied. The premagnetisation of the rod is produced by the dc anode current.

The principle advantage of magnetostriction generator is the simplicity and low cost of construction. Further of low ultrasonic frequencies, large power output is possible without the risk of damage of the oscillatory circuit system even under temporary over-load.

The main drawbacks are :

- upper limitation of frequency,

- greater dependence of frequency on temperature

- breadth of resonance curve, caused by the change in the elastic constants of ferromagnetic substances with the degree of magnetisation.

Piezoelectric Generator Effect

The piezoelectric effect is currently the most popularly used in generator for generating ultrasonic waves by converting high frequency electrical oscillations in mechanical oscillations. This is the only generator which produces higher frequency ultrasonic waves.

It utilizes the Piezoelectric effect, which means the production of a potential difference across the opposite faces of a substance, crystalline or ceramic, due to contraction or expansion between the opposite faces. This voltage appears due to the crystal lattice deformation. The application of force to a crystal of quartz or Rochelle salt produces a voltage across the crystal. Conversely, the application of an electric field may cause the crystal or expand or contract in certain directions. The piezoelectric deformations are directly proportional to the electric field and change sign when the field is reversed. The piezoelectric effect is possible only in crystals that do not possess a center of symmetry.

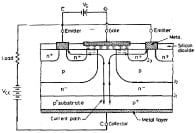

A piezoelectric quartz crystal is shown in the figure below with reference to its three sets of axes known as the Z, Y, and X axes which are at right angles to each other. In the natural form, a quartz crystal ideally takes the form of a hexagonal prism terminating at both ends in pyramids.

The schematic diagram of a quartz crystal oscillator is shown in the figure below. It is a common emitter amplifier circuit. The feedback will provide a 180° phase shift. This phase shift is provided by the quartz crystal. It may be assumed that the crystal is operating in parallel mode. Since the parallel tuned circuit provides a 180° phase shift, this meets the necessity for oscillations.

The capacitor C2 is a 0-15 pF or 0- 30 pF trimmer capacitor. Its purpose is to precisely set the frequency of oscillations. The capacitors C1 and C3 take the role of a voltage divider. It controls the amount of feedback. Excessive feedback causes distortion and drift. On the other hand, if the feedback is small, the circuit may not start every time it is started. It may be unreliable. The above circuit is capable of operating for work up to 15 MHz. If the frequency is higher, the quartz crystal thickness may be very small. The crystal may be fragile. For the achievement of higher frequencies, frequency synthesizer circuits are employed.

Characteristics of Ultrasonics

The important characteristics of ultrasonic signals are:

- Ultrasonic signals exhibit very negligible diffraction due to their small λ values. They can thus be transmitted over long distances without appreciable attenuation or loss.

- The speed of propagation of ultrasonic signals depends on their frequency, i.e., the speed decreases with a decrease of frequency.

- Ultrasound is highly energetic.

- If an ultrasonic wave is transmitted through a liquid, stationary wave patterns are generated due to the reflection of the wave from the other end. The liquid density thus changes from layer to layer along the propagation direction. A plane diffraction grating can thus be formed which can diffract light.

- Intense ultrasonic wave possesses a disruptive effect in some fluids.

Application of Ultrasonic Waves

Ultrasonic has found numerous applications in industry and communication system. Some of the applications of ultrasonics are:

- Ultrasonic as means of communication: Ultrasonic transmitters are installed in submarines, in which high-frequency sound waves are formed into a beam and set in the desired direction for detecting the presence of icebergs or submarines. A typical submarine ultrasonic transmitter uses a piezo-electric resonator.

- Coagulation and crystallization action of ultrasonics: Ultrasonics can help in coagulation and crystallization processes from a molten melt. The coagulation action of ultrasonics finds extensive use in industry for the purification of air. Thus up to 2 or 3 kilometers from the cement mill, everything gets covered with a grayish film of cement.

- Medical applications: Ultrasonic waves are very useful because they are reflected from boundaries between materials of the same density and can be used without the harmful effects of X-rays.

- Soldering of metal and welding by ultrasonic: Aluminium cannot normally be soldered. However, if the soldering is done in presence of ultrasonic waves, then aluminum can be soldered and similarly for stainless steel and some other metals and alloys. When the bit of the soldering iron radiates high-intensity ultrasonic vibrations into the molten solder, there results in cavitation and breaking up of the oxide film on the surface of the metal.

- Ultrasonic drying: Ultrasonic vibrations are used for accelerating the drying processes in certain industries. The acoustic field act is such a way that the process of drying gets accelerated.

Related Post: