Table of Contents

What is 3D printer?

The 3D printer is the latest invention of science. 3D printers can make daily life things very easily. They are amazing due to their ability to the production of various types of objects, via various kinds of materials and all these things via the same machine. It is able to make a replica of anything like ceramic cups, plastic toys, metal machines parts, stoneware vases, fancy chocolate cakes, or even (one day soon) human body parts.

A 3D printer is a computer-aided manufacturing (CAM) device that designs 3-D objects. It receives commands from a computer as input, like a conventional printer. It produces a three-dimensional model, which is different from a conventional one. The working of a 3D printer is based on the additive manufacturing process for printing physical objects layer by layer until the model is complete.

3D printer working

The working process of printing a 3D model varies according to the material used to print the object. For building a plastic model, It uses a process called fused deposition modeling (FDM). In this process, the various layers of plastic are heated and fused together. For the printing of a metallic object, a 3D printer use a process called direct metal laser sintering (DMLS).

History

- In 1964 Arthur C. Clarke (a British scientist) was the first to describe the basic functions of a 3D printer.

- In 1987 the first 3D printer system was prepared by Chuck Hull (American Scientist), which was using the “stereolithography” (SLA) process.

- In 1992 a new 3D printer based on the FDM process was released and this released by S. Scott Crump and Stratasys.

- A high-precision polymer jet fabrication system released in the market by a company called Solidscape in 1993

- In 2010 first metal parts like engine brackets and nuts produced.

- In 2013 some NASA employees make a cheap or affordable 3D printer.

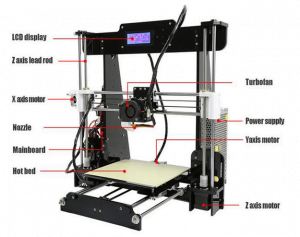

3D Printer Components

The diagram shows the key parts of a typical 3D printer, let’s understand better what these things do.

LCD Display

The LCD screen placed on the top of the printer. It used to display the information regarding the printer like temperature, the position of the head, and the progress of printing.

Z-axis lead rod

These are a pair of the road which placed vertically and used for hold or drives the head of the printer.

X-Axis motor

This is a motor/belt which controls printer movement in horizontal or X-axis.

Nozzle

This is a place where the printing material comes down when it has been heated up to the required temperature. The standard size of nozzle is 0.4 mm which is used in most of the printers.

Main board

This is the brains of the printer. It has a ardunio processor which contain whole information related to the operation which will performed. it also contains electronic motors, heater elements, USB port etc.

Hotbed

This is a platform where the desired object will printed. The range operation temperatures is between 40-600C.

Turbo Fan

It is a fan placed on the printer head for controlling the airflow to the object. It is used to cools down the printing object during the process on the heat-bed.

Power supply

Power supply placed at the back side of printer. It provides the 12 or 24 V DC power for desired operation to the electronics circuits.

Y – Axis motor

This motor is connected to the hot bed. This controls vertical movement of the hot bed during the printing process.

Z – Axis motor

This motor is placed at bottom of printer. It controls the up and down movement of the Head using two motors connected to the Z-Axis linear rods which in turn are connected to the X-axis left and right drive assembly.

Related Post: