Table of Contents

Automatic Sanitizer Dispenser Machine

The Automatic Sanitizer Dispenser Machine is an infrared movement sensor-based dispenser machine. It used to dispense any alcohol-based liquid, called sanitizer. It has a touch-less activity, which makes user fearless and comfortable about the sterilization procedure. Another name of this Automatic Sanitizer Dispenser Machine is a contact-less or touchless sanitizer dispenser machine. Because of the inbuilt movement sensor, it detects the hand movement underneath the metal nozzle and opens the valve to dispenser sanitizer.

According to the set clock, it just permits 1ml fluid at once. In the hour of the world pandemic COVID 19, the programmed hand sanitizer container is a basic item to kill the impact of the CORONA virus. The major advantage of this machine that this whole machine circuit is made without using Arduino or any type of microcontroller.

Required components

- Opamp (LM 358)

- Variable resister 10K ohm

- Resistance 10 KΩ & 100 Ω

- Photodiode (IR RECEIVER )

- IR Transmitter

- Voltage regulator (L7805, L7812)

- Relay 12V

- Transistors NPN (2n222a)

- DC female power jack

- Led red color (2.2 volts)

Short Description of used components

Opamp (LM 358): Opamp is generally an amplifier IC which is used to amplify the input voltage and it is also used as a comparator to compare the inputs and generate output difference

Variable resistor: A variable resistor is a resistor of which the electric resistance value can be adjusted. In this dispenser machine, it is used to drop the voltage at a certain level. The value of the variable resistor in this machine is 10 KΩ.

Resistance: A 100 Ω and 10 KΩ resistances are used in series with the leds. These resistances are protecting the leds from any type of damage due to high voltage.

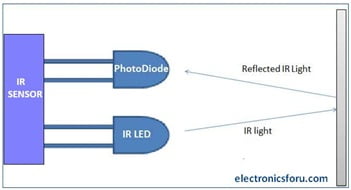

Photodiode: A photodiode is a semiconductor device that converts light into an electrical current. The current is generated when photons are absorbed in the photodiode.

In this machine, the photodiodes are used as an IR receiver. It works as a diode which uses a switch it active when it connect in reverse bias and the IR wave is transmit on it

IR Transmitter: An IR transmitter contains an LED that emits infrared light. It generates an IR wave when the voltage is applied. It is generally used in remote applications and in robotics.

Voltage regulator IC (L7805, L7812): A voltage regulator is a system designed to automatically maintain a constant voltage level. A voltage regulator may use a simple feed-forward design or may include negative feedback.

This IC this use to conduct a constant voltage either 5v or 12v. It has three terminals input, GND, output.

12V Relay: Relays are switches that open and close circuits electromechanically or electronically. Relays control one electrical circuit by opening and closing contacts in another circuit. Relay is a magnetic switch that is active when the voltage is applied to its terminals.

Transistors NPN (2n222a): The transistor is a two PN diodes back to back combination where P-type or N-type semiconductor sandwich between another type of semiconductor material. Mainly there are two types of transistors, NPN and PNP, with different circuit symbols. The letters of transistors (PNP & NPN) refers to the layers of P-type or N-type semiconductor material used to form the transistor.

In this machine, the transistor is used for as amplifier or switches it has three terminals BASE, EMITTER, COLLECTOR.

DC female power jack: This is a common barrel-type power jack for DC wall supplies. These are compatible with our DC wall supplies and have a 5mm jack, with a 2.1mm centre pole diameter. It is used connect the DC power supply to the machine.

Led red color (2.2 volts): LEDs (that’s “ell-ee-dees”) are a particular type of diode that converts electrical energy into light. In fact, LED stands for “Light Emitting Diode.”

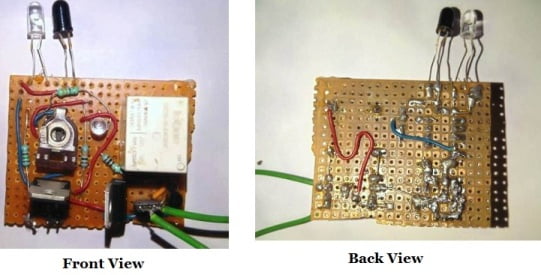

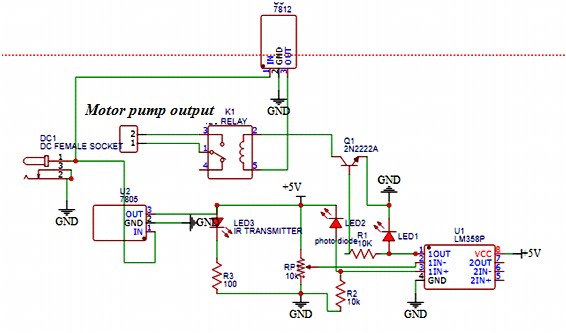

Circuit Diagram

Working of the dispenser

The working principle of the automatic sanitizer dispenser machine is based on the IR wave transmission and reception.

When the machine is switched on through the DC power supply, the IR transmitter transmits the infrared wave. The wave strikes on a surface and reflected back. Then the reflected wave is received by the IR receiver which is a photodiode here.

This IR receiver or photodiode senses the IR wave and reacts like a short switch or circuit (when it is connected in reverse bias).

Then due to connecting of resistance it doesn’t short Vcc and GND. actually it generates some voltage and this voltage is given to the opamp negative input pin

Then the opamp compare the voltage to positive input pin and the negative input pin and it generate the output voltage of difference of both input.

Now the output of the opamp connected to the base of NPN transistor which is use as switch. When some voltage is sensed by the base of the transistor. It shortens the emitter and collector of the transistor then relay is on.

Relay have 5 pins first two pin is use to on/off purpose.

The first pin is connected to +12v and the second pin is connected to the collector to the transistor and the emitter of the transistor connected to the ground. Base connected to the output pin opamp. Potentiometer or variable resistor is connected to the negative pin of the opamp which is used to set the range of the sensor.

The motor is connected to the 1 and 3 terminals of the relay. This motor is connected with the container or bottle of Sanitizer.

Applications

It mostly used in hotels, restaurants, schools, offices, homes, hospitals, factories, and industries. During the time of COVID-19, it is one of the most needed products for humans. This dispenser machine can be used mainly at the main gate on any company, school, colleges, corporate houses, banks, shopping malls, Airports, and theatres. In short, it needed at every place where person to person contact could be possible.