Table of Contents

Monochrome Picture Tube

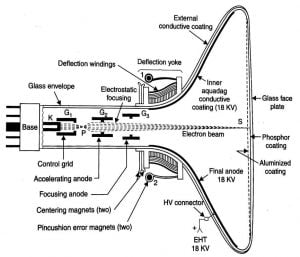

The picture tube or tv tube is a transducer to change over electrical video signals fluctuating with time into varieties of light in space to duplicate the first picture. TV tube utilizes the phenomenon of fluorescence and interlaced scanning. Modern monochrome picture tubes employ electrostatic focusing and electromagnetic deflection in tv tube.

Monochrome picture tube consists of a closed glass envelope, lodging with an electron gun to deliver a sharply focused electron beam, which sticks on a fluorescent screen to generate light. The deflection coils are mounted on the glass tube which is specially designed. Also, there is a section o deflect the electron beam in horizontal and vertical directions to control it to scan the screen along width and height to reproduce the original picture on the screen.

The different parts of the picture tube are discussed below:

Electron Gun:

It delivers a very much centered electron beam, utilizing thermionic emission of electrons from a Cathode and few grids for controlling, accelerating, and focusing the electrons.

Cathode:

The cathode is indirectly heated via the heater. The cathode consists of a cylinder of nickel that coated at its end with thoriated oxide of tungsten. This cylinder is warmed by a radiator wire set shut to the cathode yet without contacting it electrically. The material between the radiator and the cathode is a warm channel; however, it is an electric protector. This cathode is known as an indirectly warmed cathode.

and consists of a cylinder of nickel that coated at its end with thoriated oxide of tungsten which is warmed by a radiator wire set shut to the cathode yet without contacting it electrically. The material between the radiator and the cathode is a warm channel; however, it is an electric protector. This cathode is known as an indirectly warmed cathode.

Control Grid :

The next section after cathode is the control grid. It is a nickel cylinder and has a small gap between its bars, which enables the electron beam to go through. The control grid is kept at more negative potential regarding cathode and control the flow of electrons from the cathode.

Pre Accelerating Anode:

It is also nickel cylinder, which is kept at positive potential regarding cathode that varies between +300V to +600V. This anode accelerates the electron beam. Therefore this anode is called an accelerating anode.

Focusing Anode:

This anode is used to focus the electron beam using the electrostatic field to prevent spreading of the electron, this help to producing a sharp and clear spot on the screen.

Accelerating Anode:

This is the last anode which is used to accelerating the velocity of the electron beam and give a specific velocity to the electron beam, So the electron beam should hit the screen with extraordinary velocity. The required high speed is granted by the last anode, which is covered to a long directing covering of aquadag inside the tube. The aquadag covering stretches out from the screen to the thin neck. It is given an extremely high potential, called EHT.

Vertical and Horizontal Deflection Plates

The horizontal deflection plate is used to control the position of the electron beam in the horizontal direction.

The vertical plate is used to control the position of the electron beam in the vertical direction on the screen.

Fluorescent screen:

CRT screen is used to display the various signal which will be generated by the stick of electron beam on the screen. The screen is coated by a fluorescent material. The screen has a rectangular shaped an optically flat glass of high quality. This screen glass is 1.5 cm thick to bear with the outside air pressure against the internal vacuum. There is a very thin aluminum covering on the back of the phosphor surface. Which improves the brightness by reflecting the light from back to front. Additionally, the aluminum covering stops the particles to achieve the phosphor covering, which for all time harms the screen.