Table of Contents

Fiber Fabrication Methods

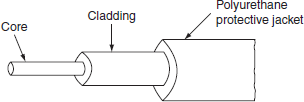

Fiber Fabrication Methods or Techniques: Fabrication of all-glass fibers is a two-stage process. The first stage consists of producing a pure glass and converting it into a rod or preform. In the second stage, a pulling technique is employed to make fibers of required diameters. Various methods are in use for producing pure glass for optical fibers.

Types of Fiber Fabrication Methods or Techniques

Fiber Fabrication Methods or Techniques may be grouped into two categories:

- liquid-phase (or melting) methods

- vapour-phase oxidation methods.

Liquid-phase (or Melting) Methods

This fiber fabrication method or Technique employs conventional glass-refining techniques for producing ultra-pure powders of the starting materials, which are oxides such as SiO2, Ge O2, B2 O3, Al2 O3, etc., which decompose into oxides during the melting process. An appropriate mixture of these materials is then melted in silica or platinum crucibles at temperatures varying from 1000 °C to 1300 °C. After the melt has been suitably processed, it is cooled and drawn into rods or tubes (of about 1 m length) of multicomponent glass.

The rod of core glass is then inserted into a tube of cladding glass to make a preform. The fiber is drawn from this preform using the apparatus shown in the figure below. Here, the preform is precision-fed into a cylindrical furnace capable of maintaining high temperature, normally called a drawing furnace. During its passage through the hot zone, its end is softened to the extent that a very thin fiber can be drawn from it. The outer diameter of the fiber is monitored through a feedback mechanism, which controls the feed rate of the preform and also the winding rate of the fiber. The bare fiber is then given a primary protective coating of the polymer by passing it through the coating bath. This coating is cured either by UV lamps or thermally. The finished fiber is then wound on a take-up drum.

A fiber 20-30 km long can be drawn from a preform of about 1 m in 2-3 h. Higher pulling rates are limited by the pulling process as well as the subsequent primary Coating operation. This method of preparing fibers tends to be a batch process and hence continuous production is not possible. Continuous manufacture is possible using another technique, which is called the double crucible method. The apparatus used is shown in the figure below.

It consists of two concentric platinum crucibles (also called a double crucible) mounted inside a vertical cylindrical muffle furnace whose temperature may be varied from 800 °C to 1200 °C. The starting material-core and cladding glasses, either directly in the powdered form or in the form of preformed rods are fed into the two crucibles separately. Both the crucibles have nozzles at their bases from which a clad fiber may be drawn from the melt in a manner similar to that shown in the figure of the Fiber-drawing apparatus. Index grading may be achieved by diffusion of dopant ions across the core–cladding interface, within the melt. Relatively inexpensive fibers of large core diameters and, therefore, large numerical apertures may be produced continuously by this method. An attenuation level of the order of 3 dB/km for sodium borosilicate glass fiber, which is prepared using this technique, has been reported.

Vapor-phase Deposition (VPD) Methods

In this fiber fabrication method or technique, the melting temperatures of silica-rich glasses are too high for liquid-phase melting techniques; therefore, vapor-phase deposition methods are used. Herein, the starting materials are halides of silica (e.g., SiCl4) and the dopants, e.g., GeCl4, TiCl4, BBr3, etc., which are purified to reduce the concentration of transition-metal impurities to below 10 ppb. Gaseous mixtures of halides of silica and the dopants are combined in vapor-phase oxidation through either flame hydrolysis or chemical vapor deposition methods. Some typical reactions are given below:

The oxides resulting from these reactions are normally deposited onto a substrate or within a hollow tube, which is built up as a stack of successive layers. Thus, the concentration of the dopant may be varied gradually to produce the desired index profile. This process results in either a solid rod or a hollow tube of glass, which must be collapsed to produce a solid preform. Various techniques have been developed based on the above principle.

Outside vapour-phase oxidation (OVPO) method

This method uses flame hydrolysis to deposit the required glass composition onto a rotating mandrel (an alumina rod) as shown in the figure below. The mixture of vapors of the starting materials, e.g., SiC14, Ge C14, BBr3, etc.. is blown through the oxygen-hydrogen flame. The soot produced by the oxidation of halide vapors is deposited on a cool mandrel. The flame is moved back and forth over the length of the mandrel so that a sufficient number of layers are deposited on it. The concentration of the dopant halides is either varied gradually, if index grading is required, or maintained constant if step-index fiber is required.

After the deposition of the core and cladding layers is complete, the mandrel is removed. The hollow and porous preform left behind is then sintered in a furnace to form a solid transparent glass rod. This is then drawn into a fiber by the apparatus discussed earlier. With a single preform, 30-40 km of fiber can be easily prepared. The index profile can be controlled well using this method, as the flow rate of vapors can be adjusted after the deposition of each layer. An attenuation of less than 1 dB/km at an operating wavelength of 1 3 µm has been reported, but the fibers show an axial dip in the refractive index.

Vapour axial deposition (VAD) method

In this fiber fabrication method, core and cladding glasses are simultaneously deposited onto the end of a seed rod, which is rotated to maintain azimuthal homogeneity and also pulled up as shown in the figure below. The porous perform so deposited, while the seed rod is being pulled up, is heated to about 1100 °C in an electric furnace in an atmosphere of O2 and thionyl chloride. Any water vapor in the preform is removed through the following reaction:

SOCl_{2}+H_{2}O\rightarrow SO_{2}+2HClThe porous preform is then heated to about 1500 °C in a carbon furnace, where it is sintered into a transparent solid glass rod.

A good control over the index profile may be achieved with germania-doped cores. Graded-index fiber with an attenuation level less than 0.5 dB/km at 1.3 µm has been produced by this method.

Modified chemical vapour deposition (MCVD) method

This is a vapor-phase oxidation process taking place inside a hollow silica tube as shown in Fig. 6.6. The tube has a length of about 1 m and a diameter of about 15 mm. It is horizontally mounted and rotated on a glass-working lathe, with an arrangement (normally an oxygen-hydrogen flame) for heating the outer surface of the tube to about 1500oC. The reactants in the form of halide vapors and oxygen are passed at a controlled rate through the tube.

The halides are oxidized in the hot zone of the tube and the generated soot (glass particles) is deposited on the inner wall. The hot zone (i.e., the flame) is moved back and forth allowing the layer-by-layer deposition of the soot. Index grading may be achieved by varying the concentration of the dopants layer by layer. The tube can form a cladding material or serve as a support structure only for the porous preform. After the deposition is complete, the tube or the porous preform is sintered at a higher temperature (1700-19000C) to form a transparent glass rod. Fiber is then drawn from this rod in the usual manner.

At present this is a widely used method for fabricating fibers, as it allows the deposition to occur in a clean environment, with reduced OH impurity. This method is suitable for preparing a variety of glass compositions for multimode or single-mode step-index (SI) or graded-index fibers. Typically, attenuation of the order of 0.2 dB/km at a wavelength of 1.55 µm has been reported for single-mode germania-doped silica fibers prepared by this method. Further, this technique is also suitable for preparing polarization-maintaining single-mode fibers.

Plasma-activated chemical vapour deposition (PCVD) method

The deposition rates of the MCVD process may be increased if microwave-frequency plasma is created in the reaction zone. This process is called plasma-activated chemical vapor deposition and is illustrated in the figure shown below. Herein, a microwave cavity (operating at 2.45 GHz) surrounds the substrate tube.

The halide vapors of the silica-based compound or the dopants along with oxygen are introduced into the tube where they react in the microwave-excited plasma zone. The tube temperature is maintained at about 1900 °C using a stationary furnace. The reaction zone is moved back and forth along the tube enabling circularly symmetrical deposition of glass layers onto the inner wall of the substrate tube. High deposition efficiency and excellent control of index grading are possible with this method. Attenuation of the order of 0.3 dB/km at λ= 1.55 µm has been obtained for dispersion flattened single-mode fibers.

Related Posts: