A TV camera tube may be called the eye of a TV system or video camera. A TV camera tube is a transducer which converts the variations of light intensity into the variation of electrical current or voltage, known as video signals. It is an essential part of a video camera.

Table of Contents

Basic Principle of Camera Tube

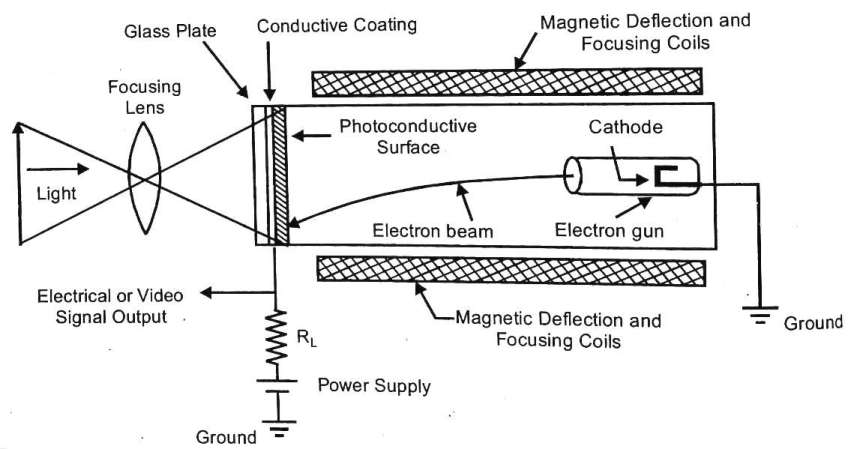

An optoelectrical converter is used to translate brightness variations into an electrical picture signal. Different converter systems are available, but only pickup tubes with a photosensitive semiconductor layer are really important for TV technology.

Any picture appears to be composed of small elementary areas of light or shade, which are known as picture elements. The elements thus contain the visual image of the scene. The purpose of a TV pick-up tube is to sense each element independently and develop a signal in electrical form proportional to the brightness of each element. Light from the scene is focused on a photosensitive surface known as the image plate, and the optical image thus formed with a lens system represents light intensity variations of the scene. By making use of photoelectric properties, the image plate then converts different light intensities into corresponding electrical variations.

Now, it is required to pick-up this information in the form of electrical charge as fast as possible. It is not possible to have a simultaneous pick-up, so scanning by an electron beam is employed. In the scanning process, the electron beam moves across the image plate line by line, and field by field to provide signal variations in successive order. This scanning process divides the image into its basic picture elements. Through the entire image, the plate is photoelectric, its construction isolates the picture elements so that each discrete small area can produce its own signal variations.

Characteristics of TV Camera Tube

- Sensitivity of visible light: Sensitivity of a camera tube should be high. It is represented in microampere per lumen.

- Spectral Response: The spectral response means the output of a camera tube for the range of wavelengths of light. In an ideal condition, the spectral response of a camera must be the same as the response of the human eye. However, practically no camera tube can give ideal result but a good camera tube gives the spectral response as close as the human eye.

- Resolution: Ability to resolve details while viewing a multielement of a scene. Resolution of camera tube depends upon the size of the spot formed by the scanning beam on the target plate. The diameter of the spot is called the aperture.

- Noise level: All electronic devices produce noise due to randomness in the number and velocity of electrons. This randomness is also referred to as self-noise. It is measured in signal to noise ratio.

- Contrast: Contrast is the brightness difference between white and black. It is the ratio between the luminance of the brightest white and the darkest black of the TV camera tube.

- Dark Current: Dark Current is the current which is always available as output from the camera tube even there is no light falls on the faceplate. Its value is in nanoamperes. Dark current is due to the availability of some free electrons at room temperature.

- Ghost effect: Ghost effect is an image of the same polarity displayed from the high light. It happens because of the sharp contrast between very bright and dark background.

Types of Camera Tubes

The first developed storage type of camera tube was ‘Iconoscope’ which has now been replaced by image orthicon camera tube. Because of its high light sensitivity, stability and high-quality picture capabilities. The light sensitivity is the ratio of the signal output to the incident illumination.

Next to be developed was the vidicon camera tube and is much simpler in operation. Similar to the vidicon camera tube is another tube known as plumbicon. The latest device in use for image scanning is the solid-state image scanner.

Production of Video Signal TV camera

Photoelectric Effects

The two photoelectric effects used for converting variations of light intensity into electrical variations are

- Photoemission

- Photoconductivity

Photo Emission

There are certain metals emit electrons when light falls on their surface. These emitted electrons are called photoelectrons and the emitting surface a photocathode. Light consists of small bundles of energy called photons.

When light is made incident on a photocathode, the photons give away their energy to the outer valence electrons to allow them to overcome the potential-energy barrier at the surface. The number of electrons which can overcome the potential barrier and get emitted depends on the light intensity. The energy of the electrons emitted from any point on the photocathode is proportional to the intensity of the light falling on that point. This process is known as photoemission.

Alkali metals are used as photocathode because they have very low work-function.

Cesium-silver or bismuth-silver-cesium oxides are preferred as photoemissive surfaces because they are sensitive to incandescent light and have a spectral response very close to the human eye.

Photo Conductivity:

The second method of producing an electrical image is by photoconduction, where the conductivity or resistivity of the photosensitive surface varies in proportion to the intensity of light focused on it. In general, the semiconductor metals including selenium, tellurium, and lead with their oxides have this property known as photoconductivity. The variations in resistance at each point across the surface of the material are utilized to develop a varying signal by scanning it uniformly with an electron beam. This process is known as photoconductivity.

Image Storage Principle

Television cameras developed during the initial stages of development were of the non-storage type. In this type of TV camera the signal output from the camera for the light on each picture element is produced only at the instant it is scanned. Most of the illumination is wasted. Since the effect of light on the image plate cannot be stored, any instantaneous pick-up has low sensitivity. Image dissector and flying-spot camera are examples of non-storage type of tubes. These are no longer in use and will not be discussed.

High camera sensitivity is necessary to televise scenes at low light levels and to achieve this, storage type tubes have been developed. In storage type camera tubes the effect of illumination on every picture element is allowed to accumulate between the times it is scanned in successive frames.

The Electron Scanning Beam

As in the case of picture tubes an electron gun produces a narrow beam of electrons for scanning. In-camera tubes magnetic focusing is normally employed. The electrons must be focused on a very narrow and thin beam. Because this is what determines the resolving capability of the camera. The diameter of the beam determines the size of the smallest picture element. Hence the finest detail of the scene to which it can be resolved.

Any movement of electric charge is a flow of current and thus the electron beam constitutes a very small current which leaves the cathode in the electron gun and scans the target plate. The scanning is done by deflecting the beam with the help of magnetic fields produced by horizontal and vertical coils in the deflection yoke put around the tubes. The beam scans 312.5 lines per field and 50 such fields are scanned per second.

Electron Multiplier

When the surface of a metal is bombarded by incident electrons having high velocities, secondary emission takes place. Aluminium, as an example, can release several secondary electrons for each incident primary electron. Camera tubes often include an electron multiplier structure, making use of the secondary emission effect to amplify the small amount of photoelectric current that is later employed to develop video signal. The electron multiplier is a series of cold anode-cathode electrodes called dynodes mounted internally, with each at a progressively higher positive potential.

The few electrons emitted by the photocathode are accelerated to a more positive dynode. The primary electrons can then force the ejection of secondary emission electrons when the velocity of the incident electrons is large enough. The secondary emission ratio is normally three or four, depending on the surface and the potential applied. The number of electrons available is multiplied each time the secondary electrons strike the emitting surface of the next more positive dynode. The current amplification thus obtained is noise-free because the electron multiplier does not have any active device or resistors.